*Note: Name, Email and Phone Number are mandatory.

Steel roofing rarely captures headlines. Yet across Africa, it is quietly emerging as one of the continent’s most investable manufacturing opportunities—driven by a massive housing deficit, infrastructure booms, and a transformative shift in the steel supply chain.

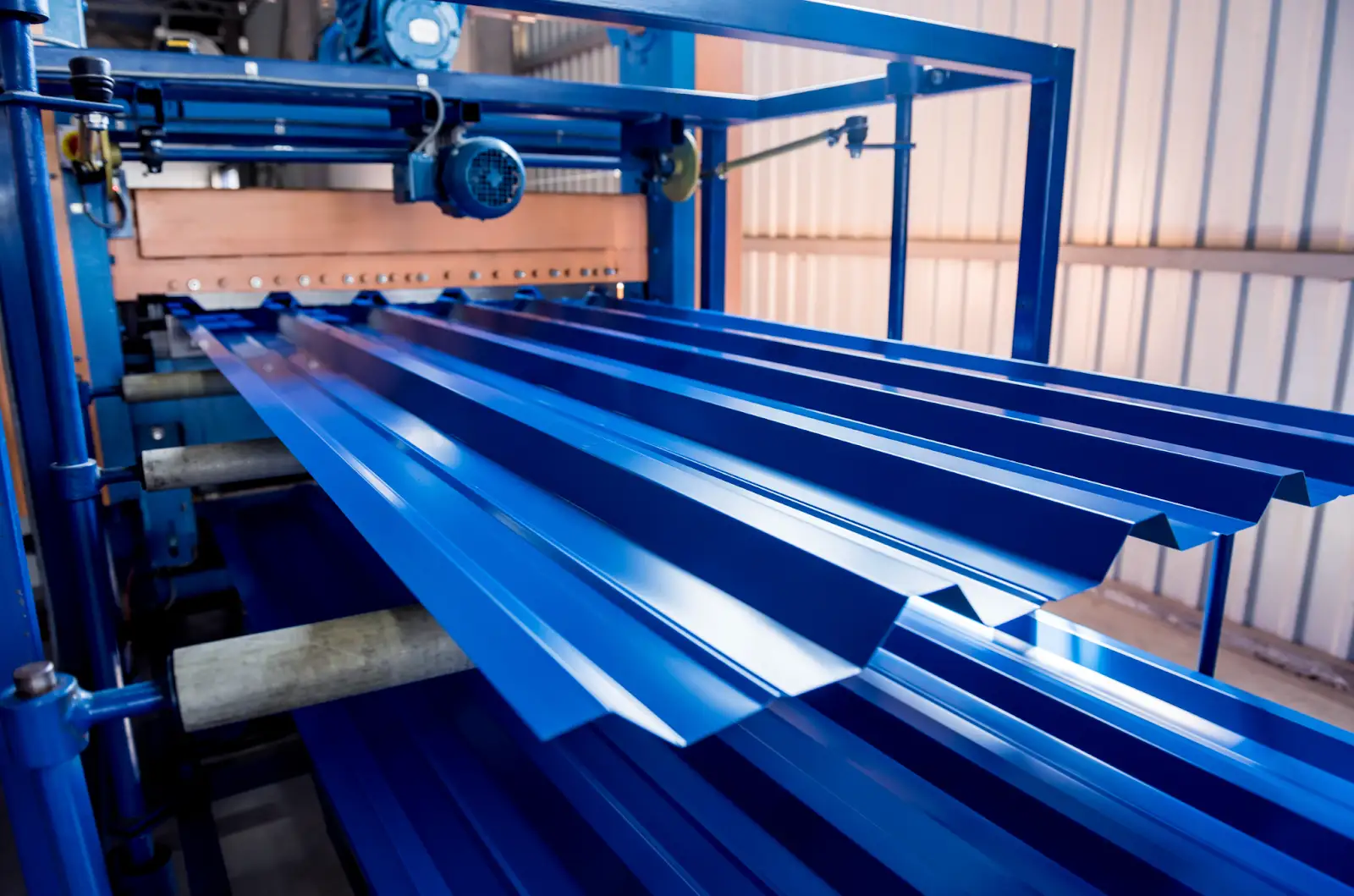

Africa’s built environment is evolving fast, and roofing materials are at the heart of this transformation. Manufactured steel roofing—lightweight, durable, and increasingly affordable—is emerging as a smart solution for housing and commercial infrastructure across the continent. But behind the sheets lies a complex ecosystem of raw materials, manufacturing hubs, sustainability efforts, and investment models. This blog unpacks the realities and opportunities, offering a comprehensive view for investors considering Africa’s steel roofing sector.

Africa’s manufactured steel roofing sector is no longer just theoretical potential—it is already delivering tangible results in several key regional markets, providing important lessons on what drives success.

In Kenya, the roofing industry has grown into a robust sector anchored by established players such as Mabati Rolling Mills. With a production capacity exceeding 40,000 tonnes annually and an estimated market size of around USD 120 million, Kenya’s steel roofing manufacturers have effectively tapped into a broad customer base that ranges from urban construction projects to rural housing. The country’s strategic location, particularly its access to the port of Mombasa, facilitates smooth exports across the East African Community, enabling manufacturers to scale beyond national borders. Investments in industrial parks in Naivasha and Tatu City—attracting over USD 150 million in recent years—have provided the infrastructure needed to support this growth, making Kenya a compelling example of how localized production combined with efficient logistics can serve varied demand patterns and price sensitivities.

Moving west, Gabon’s Special Economic Zone (GSEZ), part of the ARISE Industrial Parks network, presents another compelling example. Here, integrated steel processing and manufacturing benefit from streamlined logistics and preferential trade access, reducing both costs and delivery times. The manufacturing facilities in GSEZ produce over 15,000 tonnes of steel roofing annually and have attracted foreign direct investments totaling over USD 200 million since 2022. This hub exemplifies how a well-planned industrial park can create a complete ecosystem that supports end-to-end manufacturing—from raw steel inputs to finished roofing products. More importantly, the ARISE IIP model effectively eliminates common operational barriers faced by African manufacturers, such as customs clearance delays and infrastructure deficiencies, thereby enabling smoother market entry and competitiveness.

In the south, South Africa remains the continent’s most mature steel manufacturing hub.

With over 6 million tonnes of crude steel production annually and a roofing market estimated at USD 800 million, South Africa’s producers such as ArcelorMittal are well-established, serving both domestic markets and exports to the Southern African Development Community (SADC).

Despite facing challenges such as a 10% rise in production costs linked to energy supply instability, South African manufacturers maintain competitiveness through established infrastructure, skilled labor, and adherence to quality certifications that meet regional and international standards.

Together, these market snapshots offer more than isolated success stories. They illustrate how a combination of geographic advantages, infrastructure investment, market maturity, and supportive policies can form scalable, profitable steel roofing manufacturing hubs. For investors, these examples significantly reduce uncertainty by demonstrating proven, replicable business models that are already generating returns in Africa’s dynamic industrial landscape.

Africa isn’t just importing steel roofing—it’s sitting on the geological reserves that could power an entire manufacturing ecosystem.

The continent holds over 30% of the world’s iron ore reserves, according to Al Jazeera’s mapping of Africa’s natural resources. Countries like Guinea, Liberia, South Africa, and Mauritania command significant volumes, making Africa one of the richest sources of steel-making inputs globally.

Guinea alone is home to the Simandou range, considered one of the world’s largest untapped deposits of high-grade iron ore. And this isn’t theoretical potential—the region is now a focal point for development, supported by a mix of state-backed and private sector investment. Meanwhile, South Africa and Liberia continue to serve as legacy mining hubs, reinforcing Africa’s foundational advantage in iron ore supply.

Beyond iron, the continent is equally rich in bauxite—key for aluminium-based roofing—and zinc, used in galvanization. Together, these metals form the backbone of steel roofing production and offer the raw material base to power both domestic manufacturing and regional supply chains.

Currently, a significant portion of this raw wealth is exported in unprocessed form. But examples like the Kaduna Steel Plant in Nigeria, developed by African Natural Resources and Mines (GEM Wiki), prove that local processing at source is already happening. These integrated facilities reduce dependence on imports, cut logistical costs, and provide insulation from global commodity price shocks.

It’s a classic upstream-to-midstream integration play—and the margins speak for themselves.

In short, Africa doesn’t need to import the raw materials for roofing—it needs to industrialize around them. The reserves are real. The models are proven. What’s needed now is scale.

Advancements in steel roofing technology are enhancing its suitability for Africa's construction needs:

These innovations position steel roofing as a viable solution to meet Africa's growing housing demands efficiently and sustainably.

Africa’s roofing demand is continental. Its manufacturing footprint? Not yet.

A handful of countries are shaping up as steel roofing hubs, each with distinct advantages—but the landscape remains fragmented, making it ripe for strategic consolidation.

South Africa stands out with a mature steel industry and export-ready capacity. Players like ArcelorMittal South Africa and Safal Group are producing coated sheets for domestic and regional markets. However, rising input costs and energy instability make decentralization an increasingly attractive option.

Egypt is capitalizing on its geographic proximity to Europe and the Middle East. With robust Special Economic Zones (SEZs) around the Suez Canal, it’s emerging as a bridge between African production and global demand—especially in prefab construction exports.

Kenya, with its vibrant construction boom and expanding logistics sector, is home to small but growing manufacturers producing pre-painted galvanized iron (PPGI) and insulated roofing panels. The country’s industrial parks in Naivasha and Tatu City offer a launchpad for scalable production.

Nigeria and Ghana are in earlier phases. Both have access to raw materials and port infrastructure but lack deep industrial capacity. That’s changing fast, though, with new industrial zones like the Lekki Free Trade Zone and Tema Free Zone offering investor-friendly setups for steel-based manufacturing.

What’s missing is a continental-scale player—a vertically integrated roofing manufacturer that can service multiple subregions. Investors who move now can build that first-mover advantage across ECOWAS, EAC, and SADC.

Sustainability isn’t just a checkbox in manufacturing—it’s a growing competitive edge in African steel roofing.

Lower Emissions Through New Technologies

The global steel industry contributes around 7–9% of CO₂ emissions, but Africa currently sits below that average. However, as the continent industrializes, emissions are projected to rise—unless mitigated by green tech.

South Africa is already leading the charge. Through the "Accelerating South Africa’s Steel Decarbonisation" initiative, the country is pushing for widespread adoption of electric arc furnaces (EAFs) and direct reduced iron (DRI) methods—both of which reduce emissions by up to 70% compared to traditional blast furnaces.

Recycling: A Missed Opportunity, Now Turning Corner

Africa generates over 2 million tonnes of steel scrap annually, much of which remains underutilized. Recycling this scrap is not just cost-effective—it also drastically cuts emissions.

In South Africa, the green steel movement is gaining ground, with scrap-based EAF facilities increasingly being seen as a scalable, low-emission solution. This strategy aligns well with "circular economy" goals and appeals to both regulators and green-certified buyers. Investors in the metal recycling business too can generate big revenue.

Smarter Sheets for Greener Buildings

Sustainability isn’t just about production—it’s about performance. Roofing innovations like thermally insulated, coated steel sheets are improving energy efficiency in buildings. These are particularly impactful in African contexts where energy is either expensive or unreliable, reducing indoor cooling needs and cutting energy bills.

Hydrogen: The Frontier Fuel

Beyond recycling, some African nations are exploring green hydrogen as a game-changer. In Mauritania, major steel projects are being designed to run on renewable hydrogen, potentially making the country a pioneer in zero-emission steel production for roofing and construction.

Industrial Parks as Green Ecosystems

ARISE IIP is setting a benchmark for eco-industrial zones. Their model includes solar integration, water recycling, and centralized waste management, creating turnkey green infrastructure for manufacturers looking to meet global ESG standards from day one.

Investment into Africa’s manufactured steel roofing sector takes several shapes—from greenfield projects in emerging zones to expansions in established hubs.

Private equity and impact investors are increasingly attracted by the sector’s resilience. The affordable housing demand across urbanizing African cities drives steady consumption, with a projected CAGR of 8-10% over the next decade. According to GlobalData, Africa’s roofing market size was valued at USD 3.6 billion in 2023 and is expected to reach over USD 6 billion by 2030.

Financing models vary. Some investors prefer joint ventures with local manufacturers, leveraging their market knowledge and networks. Others back integrated industrial parks like ARISE IIP, which offer ready infrastructure, streamlined customs, and access to export markets under preferential trade agreements such as AfCFTA.

Additionally, contract manufacturing for international prefab housing firms presents another revenue avenue. Prefabricated steel roofing solutions are gaining popularity in Africa, supported by increasing modular construction trends and government housing initiatives.

In construction and infrastructure, material choice isn’t just about cost or aesthetics—it's about risk management. Roofing materials, especially those destined for large-scale housing or commercial projects, must meet stringent quality, safety, and durability standards. For manufactured steel roofing to gain traction at scale, it must be backed by credible certifications that de-risk purchase decisions and financing.

Globally recognized certifications like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) are increasingly standard for Africa’s larger steel roofing manufacturers. These certifications assure buyers that production processes are consistent, compliant, and environmentally conscious—key considerations for governments and multinational developers.

National certification bodies across Africa are aligning standards with global benchmarks:

These certifications aren’t just bureaucratic checkboxes. They open doors for manufacturers to supply major government infrastructure projects, international housing programs, and private-sector developers who require documented quality assurance. Importantly, ARISE IIP parks provide infrastructure and operational support that enable manufacturers to comply with these standards more easily, such as on-site labs and streamlined access to certification bodies.

For investors, this means the roofing products made in these parks are not just competitively priced—they are bankable. They meet the procurement requirements of development banks, multinational construction firms, and export markets in Europe and the US. This credibility significantly reduces risk and enhances the long-term viability of investments in manufactured steel roofing.

ARISE Industrial Parks (IIP) play a catalytic role in Africa’s steel roofing ecosystem. By offering ready-made infrastructure, streamlined customs processes, and investor-friendly policies, ARISE IIPs reduce the traditional barriers faced by manufacturers.

The Gabon Special Economic Zone (GSEZ), a flagship ARISE park, showcases how integrated steel production can thrive within a supportive environment. GSEZ has attracted over USD 200 million in FDI since 2022, generating thousands of direct jobs and producing steel roofing that competes regionally.

ARISE’s approach aligns with the African Continental Free Trade Area (AfCFTA) goals, enabling manufacturers to access a combined market of 1.3 billion consumers. This scalability is critical for any investor aiming to build beyond a single country.

In essence, ARISE IIPs provide the infrastructure backbone and operational efficiency that can transform Africa’s manufactured steel roofing from fragmented pockets into a continent-wide industrial success story.

Africa’s manufactured steel roofing industry is at an inflection point. With vast raw materials, growing regional hubs, advancing sustainability, and supportive investment frameworks like ARISE IIP, the sector is primed for scalable growth. Investors who act decisively can tap into this opportunity—not just to build factories, but to build infrastructure for Africa’s future.

#InvestInAfricaNow

Choose the best investment opportunities and set up your business in Africa's world class industrial zones today, securing a prominent position in the global market.

Get in touch with our Africa investment specialists or support team and expand your business in Africa today!

Q1: What are the benefits of investing in manufactured steel roofing in Africa?

Investing in manufactured steel roofing in Africa offers access to a growing construction market, abundant raw materials, and supportive industrial policies. The sector's scalability and alignment with sustainability goals make it an attractive investment opportunity.

Q2: How does steel roofing contribute to sustainable construction in Africa?

Steel roofing is durable, recyclable, and energy-efficient. Its adoption reduces environmental impact, aligns with green building standards, and supports Africa's sustainability objectives.

Q3: What certifications are essential for steel roofing manufacturers in Africa?

Key certifications include ISO 9001 for Quality Management and ISO 14001 for Environmental Management. National standards from bodies like SON (Nigeria), KEBS (Kenya), and SABS (South Africa) are also crucial for market acceptance.

Q4: Which African countries are leading in steel roofing manufacturing?

South Africa, Kenya, and Gabon are notable leaders, with established manufacturing hubs, supportive policies, and strategic investments in infrastructure.

recommended topics

Discover prime locations across Africa for lucrative investment opportunities and strategic growth.

Explore key investment zones in Africa that offer strategic advantages and economic benefits.

Uncover the best investment opportunities in Africa to maximize your business potential.

Identify the most promising sectors in Africa for high returns and sustainable investments.

Compare

Dear investor, please compare similar category items- either Locations or Opportunities.

*Already subscribed.

*Enter your name/email.

Sign up for exclusive investment alerts.

Already subscribed? Skip

Thank You For Subscribing to

Africa For Investors.

You will be redirected to AFI’s Linkedin Profile in 10 seconds.

Stay On AFI Website